|

|

|

(Reference:

Laser Marking Mechanism &

Quality Characteristics &

How to Select a Laser Marking System) |

|

|

|

Integrated

Lamp-pumped Nd:YAG Laser Marking System |

|

|

Laser marking methods offer several

advantages when compared to traditional marking and

labeling practices. A list of typical advantages might

include ability to produce high-quality permanent and

contamination-free marks, no character distortion since

the method is non-contact, easily automated and

integrated into manufacturing systems, and can have high

speeds and throughputs. The flexibility of laser marking

often helps improve the product quality, traceability,

process control, and customer satisfaction. Laser marking

systems are often more economical, especially when

applied to high production line applications. Imported

key components used in our laser marking systems result

in high performance, good beam quality & low

maintenances and low cost man-power results in low prices

of our systems. We also use high-speed optical galvanometers made in

USA for laser beam scanning and our own powerful laser

marking software. Our laser marking systems are being

widely used in laser marking of hard, fragile or soft products

or materials.

For more information on laser marking, please refer to

Application Notes. Laser marking methods offer several

advantages when compared to traditional marking and

labeling practices. A list of typical advantages might

include ability to produce high-quality permanent and

contamination-free marks, no character distortion since

the method is non-contact, easily automated and

integrated into manufacturing systems, and can have high

speeds and throughputs. The flexibility of laser marking

often helps improve the product quality, traceability,

process control, and customer satisfaction. Laser marking

systems are often more economical, especially when

applied to high production line applications. Imported

key components used in our laser marking systems result

in high performance, good beam quality & low

maintenances and low cost man-power results in low prices

of our systems. We also use high-speed optical galvanometers made in

USA for laser beam scanning and our own powerful laser

marking software. Our laser marking systems are being

widely used in laser marking of hard, fragile or soft products

or materials.

For more information on laser marking, please refer to

Application Notes.

| |

M-YAG-50

|

M-YAG-100

|

|

Laser Head |

|

Laser

type |

Lamp-pumped CW Nd:YAG lasers

|

|

Laser

wavelength |

1064 nm

|

|

Max

Laser power |

50W

|

100W

|

|

Output

stability |

+/- 3%

|

|

Cooling

method |

Closed water

cooling

|

|

Power

requirements |

380VAC, 6.5KVA

|

380VAC, 8KVA

|

|

Laser Marking

Head |

|

Scanner |

High-speed optical galvanometers

|

|

Marking field*

(mmxmm) |

100x100

(other

marking field available upon request)

|

|

Marking speed |

300

characters/second or 10m/s

|

|

Marking line

(mm) |

Min. 0.05

|

|

Marking software |

|

Various

fonts, pictures (PLT, BMP), automated series

numbers, date, time, barcodes, DataMatrix |

|

Option |

|

Laser chiller,Z-stage,

lab jack |

* Marking

field depends on scan lens (f-theta lens)

once other parameters and parts are confirmed. Large field sizes

demand the use of lenses of long focal length. In turn, this leads to

increase focused spot size and decrease laser power density on the

workpiece. Thus reasonable mark field should be carefully selected. If

both small focused beam diameter (narrow line width) and large field

are simultaneously required, a XY moving table

is recommended for best performance. |

|

|

Typical

Applications:

-

Laser marking of metal &

non-metal materials and products: stainless steel, copper, aluminum alloy,

acrylic, ceramics, plastics, organics, thermo-elastomer

rubbers, paper, scissors,

bearing, gear,

detonator

-

Electronic industry:

capacitor, inductor,

oscillator, PCB,

IC, connector, control panel,

instrument

-

Others: cosmetics, food

package, bottle, gift, advertisement & signcrafts,

craft & gift making

|

|

We can provide OEMs and system integrators with a range of

high performance components and sub-assemblies of Nd:YAG laser

markers at more attractive prices. These components and sub-assemblies

are laser head (pump

chamber with Nd:YAG rod and

lamp, laser resonator, Q-switch cell,

optional aperture, optional beam expamder),

Q-switch driver, lamp driver,

marking head, marking software,

chiller,

stage. For more detailed information and their

prices, please go to

OEM Lamp-pumped Nd:YAG Laser

Markers. |

|

|

|

|

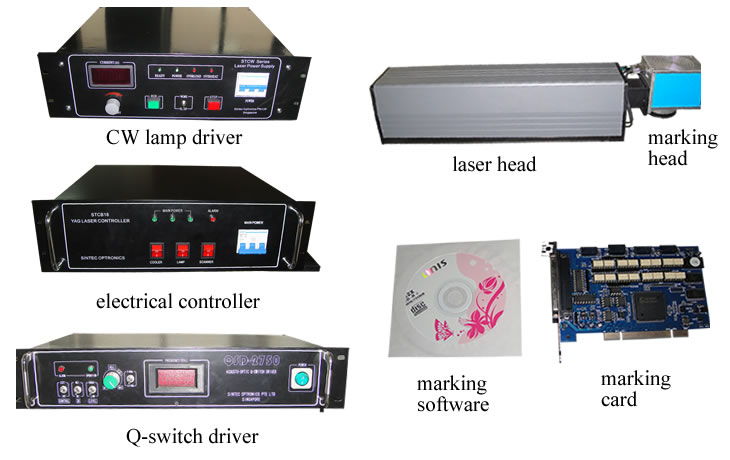

OEM

Lamp-pumped Nd:YAG Laser Marking System |

|

|

We can provide OEMs and

system integrators with a range of high performance

components and sub-assemblies of Nd:YAG laser markers at more attractive

prices. These components and sub-assemblies are laser head (pump

chamber with Nd:YAG rod and lamp,

laser resonator, Q-switch cell, optional beam expamder), Q-switch

driver, lamp driver, electrical

controller, marking

head, marking software, chiller,

stage. |

| |

|

Model Number |

Description |

Option |

|

M-YAG-50OEM |

50W

laser marker, including laser head with

mark head

LSCT-1064-12-110-6231, lamp driver STCW22A, Q-switch driver QSD2750,

electrical controller STCB18, LMX-1 marking card and marking software |

chiller

ST-LW52-BHP |

|

M-YAG-75OEM |

75W

laser marker, including laser head with mark head

LSCT-1064-12-110-6231, lamp driver STCW22A, Q-switch driver QSD2775,

electrical controller STCB18, LMX-1 marking card and marking software |

chiller

ST-LW72-BHP |

|

M-YAG-100OEM |

100W

laser marker, including laser head with mark head

LS-1064-12-110-6231, lamp driver STCW32A, Q-switch driver QSD27100,

electrical controller STCB18, LMX-1 marking card and marking software |

chiller

ST-LW72-BHP |

Remark:

marking head LSST can be used to replace marking head LSCT at much

lower prices. |

| |

|

| |

| 1.

Laser Head with Marking Head |

|

A laser head consists of

laser base (optical rail), pump chamber

with a lamp and a YAG rod, output

coupler and rear mirror with mounts, front plate, rear plate, and cover. Options

include aperture, AO Q-switch cell and

beam expander with

mount. |

|

|

|

A laser marking head consists of scan mirrors,

galvanometers & drive cards, galvanometer mount,

scan lens (f-theta

lens), marking card (PCI slot) and marking software (under Windows XP). |

|

|

|

|

|

|

|

2.

Q-switch Driver |

|

|

|

The panel

is standard 19 inch. |

|

|

|

|

3. Lamp Driver

The panel is standard 19 inch.

|

4.

Electrical Controller

Including

DC power supply of the marking head, replays, buttons, indicators,

alarms

etc.

|

|

Dimensions of OEM Laser Marker:

laser

head and marking head: 1120*170*180mm

controller: 483*500*135mm

Lamp

driver: 483*500*135mm

Q-switch driver: 483*90*350mm

Pack

Information

There

are two wooden boxes. One box includes laser head and marking head and

another includes controller, lamp driver and Q-switch driver. Their pack

dimensions and weights are roughly as follows:

580x530x630mm, 52kg; 1310x300x900mm, 45kg.

|

|

Diode-pumped Laser Markers Fiber

Laser Marker CO2 Laser Markers

Deep Laser Engraver

Diode-pumped Laser Markers Fiber

Laser Marker CO2 Laser Markers

Deep Laser Engraver |

|

Download datasheet

"Nd:YAG Laser marking

systems" in PDF |

|

(Reference:

Laser Marking Mechanism &

Quality Characteristics &

How to Select a Laser Marking System) |

|

|

|