|

1.

ST-FFP

Series Far Field Profilometer Instrument

ST-FFP far field

measurement instrument is a stand-alone device for measuring light intensity vs

output angle of light emitting components such as high optical power laser diode

bars and other high intensity light sources.

Features

� Standard

input wavelength range 400-1700 nm

� Input

optical power up to 100W CW

� Scanning

angle range �90�

� Angular

resolution 0.03�

� High

dynamic range of >60 dB

� Noise

free measurement of pulsed light

� USB

connection, easy to use software

� Advanced

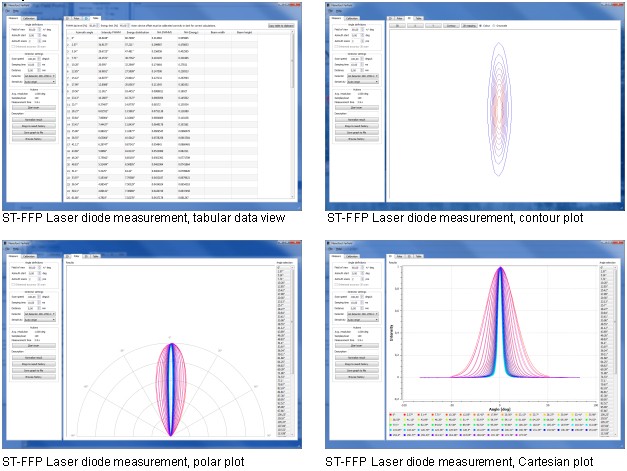

plotting features: 1D, 2D, 3D and contour plots

� Tabular

data displaying FWHM and NA

� Export

measurement data into various formats

� Fixtures

for FC, SMA fibers and various LEDs and lasers available

� Maintenance

free

Applications

� Light

emission intensity vs output angle analysis (a.k.a. far field)

� High

optical input power capability

� Numerical

aperture characterization of optical components

� Designed

for high power laser diodes

� Automated

laser diode quality assurance

� Suitable

for LED, laser diode, laser bar and fiber

Specifications:

|

Model |

ST-FFP-VIS-IR |

ST-FFP-RGB |

Customized |

|

Wavelength

range |

500 � 1700

nm |

Separate

R,G,B channels |

From 200 to

3000 nm |

|

Field of

view |

+/- 89� |

+/- 89� |

+/- 89� |

|

Light input

aperture |

30 mm or

SMA/FC fiber mount |

30 mm or

SMA/FC fiber mount |

1-50 mm,

custom shape |

|

Agnle

resolution |

0.03� |

0.03� |

0.03� |

|

Angle

resolution in 3D scans |

0.05� |

0.05� |

0.05� |

|

Azimuth

resolution |

0.01� |

0.01� |

0.01� |

|

Optical

input power |

50 �W �

100W |

50 �W �

100W |

10 �W �

200W |

|

Dynamic

range |

>60 dB |

>60 dB |

Up to 90 dB |

|

Sampling

time |

1.3 � 1000

ms |

1.3 � 1000

ms |

1 �s � 1 h |

|

Scanning

speed |

0.05 � 300

�/s |

0.05 � 300

�/s |

0.05 � 300

�/s |

|

Photodiode

sensitivity ranges |

5 decades |

5 decades |

5 decades |

|

PC

conncetion |

USB |

USB |

USB or

custom |

|

Programming

interface |

ASCII text

commands through virtual COM port, optional C# library with examples |

ASCII text

commands through virtual COM port, optional C# library with examples |

Standard or

customized |

|

Power |

12 V DC 1.5

A |

12 V DC 1.5

A |

12 V DC 1.5

A |

|

Dimension

|

305x331x335mm |

305x331x335mm |

305x331x335mm |

|

Weight

|

10kg |

10kg |

10kg |

|

Approvals |

CE |

CE |

CE |

|

Software

operating system |

Windows

2000 or later,

32 or 64

bit OS |

Windows

2000 or later,

32 or 64

bit OS |

Windows

2000 or later,

32 or 64

bit OS |

|

Data

display |

Cartesian,

polar, 3D, contour, table |

Cartesian,

polar, 3D, contour, table |

Cartesian,

polar, 3D, contour, table |

|

Export

formats |

CSV, PDF,

PNG, PS, XML |

CSV, PDF,

PNG, PS, XML |

CSV, PDF,

PNG, PS, XML |

Capabilities

2.

ST-LDC

Series Automated Laser Diode/Bar Characterization & Testing Systems

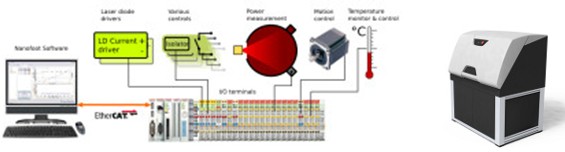

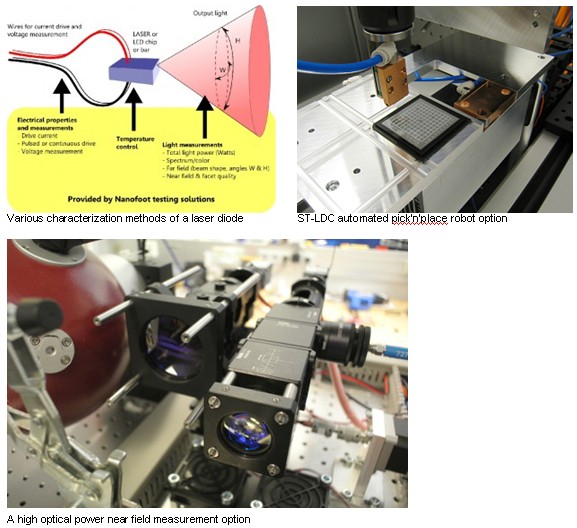

ST-LDC systems are

fully configurable, all-in-one laser diode and LED characterization devices for

industries and R&D laboratories. They�re designed to measure and analyze all

major characteristics of laser diodes and LEDs in a fast and reproducible way.

They�re ideal tool for data sheet generation, quality control, failure analysis

and research activities with semiconductor emitters.

ST-LDC systems are

customizable tool to meet various needs required by different activities. They

can measure devices from UV-LEDs to telecom laser diodes and high power laser

bars, we can features a camera assisted pick�n'place robot capable of collecting

diodes from customer supplied trays and finally marking and sorting them after

the tests.

Architecture

ST-LDC systems are

having modular construction based on robust field bus technology. This

construction makes high scalability and easy maintenance possible while keeping

number of components minimum.

On ST-LDC system

without pick�n'place robotics, devices under test (DUTs) are loaded into the

system on multichannel

load-trays

that are equipped with an individual low resistance bypass switch over each DUT

to allow series connected devices operating even in case of open circuit or

empty slots. Load tray also features channel specific temperature and voltage

monitors and optionally a channel specific temperature control.

ST-LDC capabilities

|

|

Value |

Remarks |

|

DUT type |

Laser

diode, Laser bar, LED, HB LED, UHB LED |

Multiple

DUT adapters are possible with single ST-LDC |

|

DUT current

driver |

> 0-500 mA

(CW and/or pulsed)

> 0-5 A (CW

and/or pulsed)

> 0-20A (CW

and/or pulsed)

> 0-60A (CW

and/or pulsed)

> 0-120A

(CW and/or pulsed)

> 0-200A

(pulsed only)

> 0-400A

(pulsed only) |

Multiple

drivers are possible within single ST-LDC |

|

Load-tray support |

Yes |

|

|

Power

measurement (LIV) |

0-200 W

optical, 300 � 3000 nm |

Various

accuracy and calibration options available |

|

Spectrum

measurement |

200 � 2400

nm, resolution from 10 pm to 1 nm |

Based on

OSA or spectrometer |

|

Far field

measurement |

See ST-FFP

specifications |

|

|

Visual

ispection |

Near field

integrity test |

Available

as low and high power type |

|

DUT

operating condition control |

> TEC/peltier

based, up to 30W cooling capacity per DUT, fast temperature variation

possible

> Water

cooled, up to 400W cooling capacity

per DUT

> Nitrogen

atmosphere optional

> Humidity

control optional |

Microchannel DUT support only with water cooling |

|

By-emitter

measurements |

Spectrum,

LIV, Polarity |

Only laser

for diode bars |

|

Throughput |

Depends on

the ordered options, contact us to receive throughput calculations |

|

|

Dimensions |

1200 x 900

x 1500 mm |

|

|

Weight |

200 kg |

|

|

Power |

220-240 V

AC 5 A |

|

|

Approvals |

CE |

|

ST- LDCrobo

additional capabilities

|

|

Value |

Remarks |

|

DUT type |

Laser

diode, Laser bar, LED, HB LED, UHB LED |

Multiple

DUT adapters are possible with single ST-LDC |

|

Functions |

> Locate

and measure chip position

> Pick chip

> Align and

place on testing bench

>

Optionally mark chip

> Place

chip: Back to the original tray, Sort to different trays, Discard |

|

|

Machine

vision alignment |

Included |

|

|

Throughput

(standard model) |

Up to 3 DUT

per minute |

Time varies

by the tests to be performed, contact us for calculation |

|

Throughput

(high volume model) |

Up to 10

DUT per minute |

Tailor made

system for specific testing needs, contact us for calculation |

|

Bare chip

handling |

Yes |

DUT�s

supplied in a Gel-pak� |

|

Mounted

chip handling |

Yes |

Customer

specific DUT trays |

|

Available

accuracy grades |

> Basic:

+/- 20 �m

> High: +/-

10 �m

> Extreme:

+/- 1.25 �m |

|

|

Dimensions |

1200 x 900

x 1500 mm |

|

|

Weight |

200 kg |

|

|

Power |

220-240 V

AC 5 A |

|

|

Approvals |

CE |

|

Software:

|

|

Value |

Remarks |

|

Operating

software |

Measuretool |

|

|

Result

viewer & analysis tool |

Result

browser |

|

|

Common

Measurement Database (CMDB) |

Yes |

|

|

Operating

system |

Windows 7

32 bit |

Supplied

within LDC computer (included) |

|

Optical

Data analysis

|

Ith, Slope

Efficiency, Wall plug efficiency |

|

|

Electrical |

Rs, Vbias |

|

|

Thermal |

T0, T1 |

|

|

Spectrum |

dλ/dT, SMSR,

peak λ, FWHM |

|

|

Far field |

FWHM, Beam

Steering |

|

Capabilities:

3.

ST-BLT & ST-BLTnano Series Laser Diode Burn-in & Life-time Testers

ST-BLT

series burn-in testers are designed for laser diode manufacturing industry.

Stand alone ST-BLT test stations are optimal for high power laser diode burn-in

testing and quality assurance. Unique characterization features of ST-BLT

testers make them also suitable for simultaneous laser diode characterization

and data sheet generation. Each ST-BLT system is assembled to meet customer�s

specifications on laser bar optical power, mechanical dimensions, measurement

features and throughput.

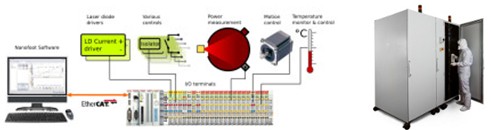

A typical ST-BLT

system consist simultaneous burn-in station for 10 to 50 high power laser diodes

or bars each emitting up to 150 W of optical power. A system uses shared

measurement instruments and laser diode temperature controller for all laser

bars making it very cost effective

solution when

compared to competing systems.

ST-BLT

systems have modular construction based on robust field bus technology. This

construction makes high scalability and easy maintenance possible while keeping

number of components minimum. Multiple ST-BLT systems can be operated from a

single control computer. Devices under test (DUTs) are loaded into the system on

multichannel

load-trays

that are equipped with an individual low resistance bypass switch over each DUT

to allow series connected devices operating even in case of open circuit or

empty slots. Load tray also features channel specific temperature and voltage

monitors and optionally a channel specific temperature control.

ST-BLT

specifications,

on-line measurement model

|

|

Value |

Remarks |

|

Product

name |

ST-BLT |

|

|

Scalability |

1-64 ST-BLT

cabinets per one system |

|

|

DUT types |

Laser

diode, Laser bar, HB LED |

|

|

Load-tray support |

Yes |

|

|

On-line

measurements |

LIV,

Spectrum, Temperature |

|

|

Measurement

cycle |

User

definable |

|

|

Current

drive |

Up to 200 A

CW or pulsed, up to 20 kW per cabinet |

|

|

Temperature

control |

Water

cooling with chiller

TEC/peltier

with individual DUT temperature setting |

|

|

Safety &

DUT fault detection |

E-stop,

Over-temperature, Smoke detector, Short circuits, Open circuits, Optical

property change |

|

|

Dimensions

(W x H x D) |

700 x 1800

x 1200 mm |

Typical |

|

Power |

3 phase AC

380 VAC |

|

ST-BLTnano,

blind, non-characterizing type

|

|

Value |

Remarks |

|

Product

name |

ST-BLTnano |

|

|

Scalability |

1-64

BLTnano cabinets per one system |

|

|

DUT types |

Laser

diode, Laser bar, LED, HB LED |

|

|

Load-tray support |

Yes |

|

|

On-line

measurements |

Voltage,

Temperature |

|

|

Measurement

cycle |

Continuous |

|

|

Current

drive |

Up to 100 A

CW or pulsed / up to 1 kW |

|

|

Temperature

control |

Water

cooling with chiller |

|

|

Safety &

DUT fault detection |

E-stop,

Over-temperature, Smoke detector, Short circuits, Open circuits |

|

|

Dimensions

(W x H x D) |

700 x 500

210 mm |

Typical |

|

Power |

1 phase 230

VAC |

|

4.

ST-VIS Series Visual Inspection System

ST-VIS is dedicated

tool for laser bar inspection in production environment. This system inspects

around 50 laser bars in hour for any visible defects in (sub threshold) near

field or at surface of exit facet. While doing this system provides also

accurate measurement from laser bar overhang and smile.

ST-VIS classifies

all images and measurement results to passed / failed by internal criteria /

failed by external criteria. These rulings may be used to see which bars can be

sold, when bars can be sold although they have some defects and when bars are

too defective to be sold. ST-VIS also provides systematic way to find defects.

For example result stored to database can be: Emitter 18 had too large defect,

and its overhang was too big (22.1 �m).

Features:

� ST-VIS

replaces operator in labour intensive facet inspection and provides key

advantages

� Defects

are found every day � every hour. System does not have bad days and it does not

get tired.

� Simultaneous

near field inspection provides enhanced way to find faulty devices

� All

results are systematically logged and easily accessible afterwards.

Facet and

Near-Field inspection

The facet

inspection option can be used to detect particles, cracks and coating defects

down to 1 �m in diameter. With this option a microscope is used to take an image

from front facet which can be analyzed either by the user or by machine vision

software.

We have developed

measurement modes that work in conjugation with facet inspection using same

camera and opto-mechanics. These new measurement options are sub-threshold NF

imaging and overhang measurement. Sub threshold imaging of NF helps system to

find defects that are difficult to find using regular machine vision imaging

methods. This option provides enhanced defect detection. With this mode facet

inspection (NF and visual) and overhang measurement can be done in less than 75

s per bar (19 visual inspection images, 19 NF images and overhang measurement).

This enables inspection of more than 300 laser bars per day.

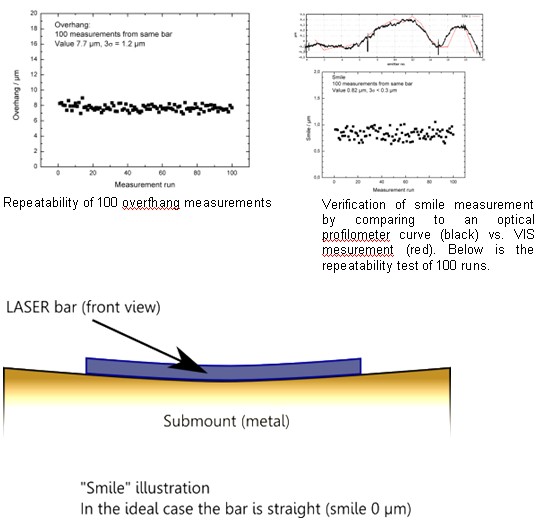

Overhang

measurement

Second new mode,

overhang measurement, allows system to use focus data from laser diode facet and

from submount to determine overhang of laser bar. Overhang of the bar is

measured from both edges of bar and for single emitters measurement is done at

the centre. This verification is important in order to qualify bar mounting

process.

Smile

measurement

High precision

smile measurement entity. Contains high resolution low distortion microscope and

enhanced vibration isolation. This can be used to measure laser bars smile with

+/- 0.2 �m accuracy (95% of confidence). Although system is vibration isolated,

due to extreme accuracy of measurement, system must be installed in space

without excessive noise and vibrations to reach specified accuracy.

Configurations:

ST-VIS

cameras ST-VIS result studio

Specifications:

|

Property |

Value |

Remarks |

|

DUT�s per

Load tray |

8,16 or 24 |

|

|

Throughput |

0.5-2 DUTs/min |

For 19-47

emitter bars |

|

Particle

regognition |

1 �m |

|

|

Near-field

continuity check |

Yes |

|

|

Smile

measurement resolution |

100 nm |

|

|

Smile

measurement repeatability |

+/- 250 nm |

Typical |

|

Overhang

resolution |

100 nm |

|

|

Overhang

repeatability |

+/-1�m |

Typical |

|

Near-field

laser drive current |

0.1-100 mA |

Auto-adjusting |

|

SQL

database support |

Yes |

|

|

Offline

results browser |

Yes |

|

|

Dimensions |

1200 x 750

x 1500 mm |

|

|

Weight |

220 kg |

|

|

Power |

230 VAC,

5A, 1-phase |

|

|

Agencies |

CE |

|

Capabilities:

Repeatability of

100 overfhang measurements

Optical fiber analyzer Optical fiber analyzer |