|

1.

Multifunctional

Laser Welding Machine

The W

series of pulse Nd:YAG laser welding systems are suitable for a wide

range of precision spot & seal welding and cutting applications in the

electronics, medical, automotive and fine mechanics markets. Typical

applications include:

� Welding

of stainless steel, aluminium alloy and other metals

� Welding

of electron guns, titanium capacitors

� Spot

welding of optical fiber coupler parts

� Welding

of containers

� Seal

welding of lithium batteries

Laser

welding has a number of advantages over conventional techniques

including:

� low

heat input

� reduced

distortion

� no

mechanical forces

� no

tool wear and hence

� consistent

weld penetration

W series

laser welding systems use optical beam delivery. An assistant gas nozzle

is also provided. CNC control system provides a convenient programming

on the welding/cutting speed, pattern, laser beam on/off, gas on/off.

The laser power is adjustable by setting laser pulse width, pulse

repetition rate and lamp operation current.

A laser

welding system typically consists of laser head, switching power supply,

CNC control system, beam delivery, motor-driven XY stage & chiller.

|

Model |

W-xxx1) |

|

Laser type |

Flashlamp-pumped pulsed Nd:YAG laser |

|

Laser wavelength |

1064nm |

|

Laser power |

50

to 400W depending on model |

|

Laser beam diameter |

5-8mm depending on model |

|

Max. laser energy |

30-100J depending on model |

|

Pulse width |

0.1-10ms, adjustable |

|

Pulse repetition rate |

1-200Hz, adjustable |

|

Focused beam diameter |

<0.2mm |

|

Beam delivery |

Optical beam delivery with a gas nozzle |

|

Internal cooling |

Closed water cooling with chiller |

|

Table |

Motor-driven XY table with 200x200mm moving range2) |

|

Power requirements |

380VAC, 3-phase, 50Hz |

Remark: 1)

W-xxx: xxx means laser power in watt. It is from 50 to 500W.

2) Other

laser welding systems available upon request.

Options:

l Microscope

l Monitor

with CCD camera

l OEM

configurations available (individual laser head with beam delivery,

laser power supply etc).

l Enclosure

2.

Mould

Laser Spot Welding Machine

The

multi-purpose laser welding system (also called as laser mould welder,

mould repair)

is specially designed for the mould industry and used in repairing of

precision moulds, such as mould manufacture for digital products, mobile

phone, toy, automobile and motorcycle, and moulding industry. Through

the repairing of moulds, it is possible to reuse the moulds, save the

production cost and improve the working efficiency significantly. This

technology can also be used to modify the design or size of moulds to

reduce the development period.

Features

The working

principle of this laser deposition welding system is to use laser high

thermal energy and the melting technology in spot to process the welding

and repairing of minute parts. It makes up the shortage of traditional

hydrogen arc welding in repairing precision surfaces, avoids the two

difficulties of thermal strain and after-treatment, and saves the

production period of mould.

Advantages

It is

specially designed for the mould industry and the technology is imported

from Germany. With unique structure design, it is suitable for repairing

of large, medium and small moulds.

1.

Ceramic

converging cavity is imported from the Britain. It is corrosion

resistant and high temperature resistant, and has 8-10 years service

life. The life of xenon lamp is more than 8 million times.

2.

Use the

most advanced light shielding system to eliminate the irritation to eyes

by light during working.

3.

The laser

head and optics part can be rotated for 360�, upward/downward lifting

and forward/backward pushing, suitable for repairing of large, medium

and small moulds.

4.

The

parameters are controlled by intelligent remote controller, which is

simple and convenient.

5. The work

bench can be lifted, and moved in three dimensions, the size of light

spot can be adjusted.

Suitable materials

The

materials that can be welded are extensive: cold work alloy steel, hot

work alloy steel, nickel tool steel, high grade steel, steel alloy, high

tenacity aluminum alloy, etc.

Technical

data

|

Model |

WY180 |

|

3-axis stroke of work bench |

X=300mm, Y=200mm (X, Y can be adjusted manually and Z-axis can

be manually motorized to lift maximum 250mm.) |

|

Bearing of work bench |

≤200kg |

|

Device weight |

300kg |

|

Power supply |

220V�10%/50Hz or 380V�10%/50Hz |

|

Laser parameters |

Laser parameters |

|

Laser type |

Nd:YAG pulse |

|

Adjusting range of light spot |

0.1-0.3mm |

|

Size of light spot |

0.2-3.0mm |

|

Laser wavelength |

1064nm |

|

Pulse width |

≤20ms |

|

Maximum laser power |

180W/200W |

|

Pulse frequency |

≤15Hz |

|

Laser output focus length |

50mm/100mm/120mm (optional) |

|

Laser cooling |

Water cooling |

|

Observing system |

Microscope (360� adjustable) |

|

Protection gas |

One

line (xenon) |

|

Welding wire diameter |

0.1mm-0.6mm |

Options:

l Microscope

l Monitor

with CCD camera

l OEM

configurations available (individual laser head with beam delivery,

laser power supply etc).

l Enclosure

This laser welder uses galvanometer scanning method,

features high welding speed, high precision and good light beam mode,

and is suitable for precision laser spot welding of various parts.

During single spot welding, the working efficiency is 4-10 times higher

than common laser spot welding because the idle stroke positioning time

is significantly reduced. The scanning laser welder consists of YAG

solid laser, laser power supply, optical scanning system, 3D adjustable

work bench, industrial PC system, cooling system, laser indication

system and operating cabinet.

This welder provides dedicated laser welding software

based on Windows platform. The welding spots or graphs can be imported

and edited in the dedicated software, or edited in other software such

as AutoCAD and CorelDraw and then processed in the dedicated software.

This welder features stable quality, convenient operation and easy

maintenance.

Application:

This welder is mainly used in highly efficient laser spot

welding or seal welding of mobile phone shielding case, mobile phone

metal shell, capacitor metal shell, metal shielding grid in computer,

shaver blade, electronic connector and other electronic products.

|

Model |

WG100/200 |

|

Laser type |

Nd:YAG |

|

Laser wavelength |

1064nm |

|

Maximum laser power |

100W/200W |

|

Pulse width |

≤20ms |

|

Pulse frequency |

≤50Hz |

|

Spot welding speed |

≤15 spots/s |

|

Size of light spot |

0.2-3.0mm |

|

Adjusting range of light spot |

0.1-0.3mm |

|

Maximum positioning speed |

≤7000mm/s |

|

Resolution |

0.001mm |

|

Repeating precision |

0.002mm |

|

Cooling |

Water cooling |

|

Master unit dimensions |

1600*800*1500mm |

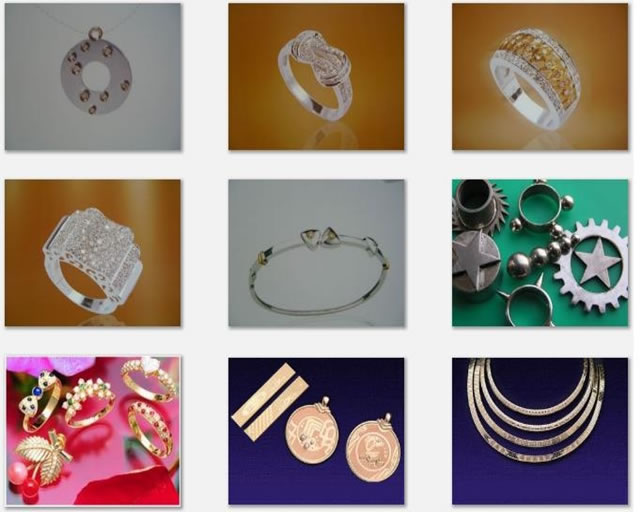

5. Welded Samples

|