|

Beam Shaper / Top-hat

A

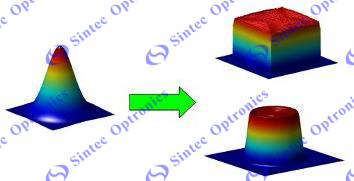

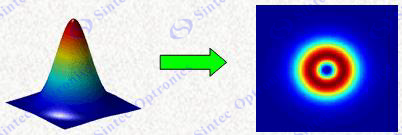

Top-Hat beam shaper converts a Gaussian input laser beam into a uniform

intensity beam of any shape and size requested by the customer. The beam shaping

element is a diffractive optical element (DOE) used to transform a near-gaussian

incident laser beam into a uniform-intensity spot of either round, rectangular,

square, line or other shape with sharp edges in a specific work plane. A

Top-Hat beam shaper converts a Gaussian input laser beam into a uniform

intensity beam of any shape and size requested by the customer. The beam shaping

element is a diffractive optical element (DOE) used to transform a near-gaussian

incident laser beam into a uniform-intensity spot of either round, rectangular,

square, line or other shape with sharp edges in a specific work plane.

A

uniform spot enables equal treatment to a surface, excluding over/under-exposure

of specific areas. In addition, the spot is characterized by a sharp transition

region that creates a clear border between the treated and untreated area.

The beam shaping can be a:

| Focal

Beam Shaping: |

Hybrid element

(lens) or module which give a Top-Hat intensity distribution at a

specific working distance (BFL of the lens or distance from exit

location of the module to Top-Hat plane). |

| Angular

Beam Shaping: |

Optical element

(window) which gives a Top-Hat intensity distribution at infinity or

focal length of aberration free customer's lens. |

|

M-Shaper: |

Optical element

(window) which gives a uniform exposure over scanned lines. |

Small Angle Top Hat standard

Small Beam Shaper for scanning application (~1.5X Diffraction Limit)

Laser beams with Top-hat energy distribution are being used for different

applications in the laser material processing industry. Most systems in this

industry include scanners and F-θ lenses in order to direct and focus the beam

on the substrate. HoloOr is proud to introduce a new design for

~1.5x(Diffraction limit) beam shapers DOEs (Diffractive Optical Element) which

is considerably cheaper than regular Top-hats.

Those DOEs are specially designed to operate with scanners/F-θ lenses under high

power lasers. Placing the beam shaper DOE before the scanner will create a

top-hat energy distribution at the F-θ lens working plane. The use of this beam

shaper does not affect the focal length of the system.

Homogenizer / Diffuser

Homogenizer product line flexibly converts any collimated input laser beam into

a well-defined beam with homogenized intensity and desired shape.

Using our Beam Homogenizer product, you can convert any collimated input beam

profile into a well-defined beam with homogenized intensity. Any desired shape,

for any wavelength can be achieved.

A Beam Homogenizer is very useful in many applications requiring a well-defined

beam shape with a randomly-diffused intensity profile.

The output of the Beam Homogenizers will depend on the input beam profile:

A multi-mode laser beam actually has an advantage when used with beam

homogenizer, as their degraded coherence will reduce the visibility of speckles

and therefore create a more uniform intensity profile than with single mode

laser input.

|

|

|

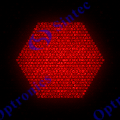

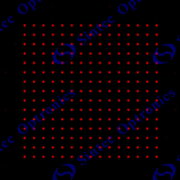

| Square Homogenizer

|

Hexagonal Homogenizer |

Round Homogenizer |

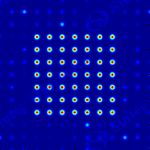

Beam Splitter

MultiSpot

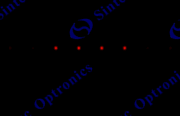

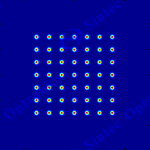

A Beam splitter element converts input laser beam into a 1 or 2-dimensional

array of beamlets according to custom parameters.

The Diffractive Beam Splitter is a diffractive optical element used to split a

single laser beam into several beams, each with the characteristics of the

original beam (except for its power and angle of propagation).

A diffractive beam splitter can generate either a 1-dimensional beam array (1xN)

or a 2-dimensional beam matrix (MxN), depending on the diffractive pattern on

the element. The diffractive beam splitter is used with monochromatic light such

as a laser beam, and is designed for a specific wavelength and angle of

separation between its output beams.

In this section, we present our standard list of 1D, 2D, and custom diffractive

beam splitters.

We offer, in addition to standard diffractive beam splitters, the possibility to

choose the number of spots and their locations, as a part of its custom design

and manufacturing capability.

We also offer Binary Phase Gratings, which is a special case of 1D Damman

grating with a duty cycle of 50% within a period. The gratings are transmission

grating. In addition to standard gratings, We offer gratings with custom

specifications (duty cycle, modulation depth, period, reflection or transmission

grating).

|

|

|

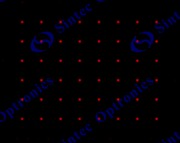

| Beam

Splitter 1x4 |

Beam

Splitter 1x7 |

Beam

splitter 15x15 |

|

|

|

| Beam splitter 6x8

|

Hexagonal Beam Splitter |

Round beam splitter |

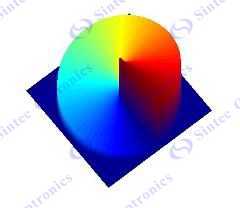

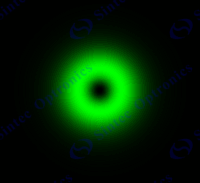

Vortex Lens

Vortex lenses convert a Gaussian input laser beam into a donut-shaped energy

ring.

A Vortex lens is a unique optic, whose structure is composed of spiral or

helical phase steps.

A Spiral phase plate converts a Gaussian input profile into a donut-shaped

energy ring.

The spiral phase plate is a unique optic, whose structure is composed entirely

of spiral or helical phase steps, whose purpose is to control the phase of the

transmitted beam.

The topological charge, denoted in the literature as m, refers to the number of

2π cycles (i.e. "staircases") etched around 360° turn of diffractive surface.

One main effect of a higher topological charge is an increase in the angular

momentum of the vortex beam by a factor of m. Another effect is the dimensions

magnification of the ring intensity pattern, by a factor of m.

|

|

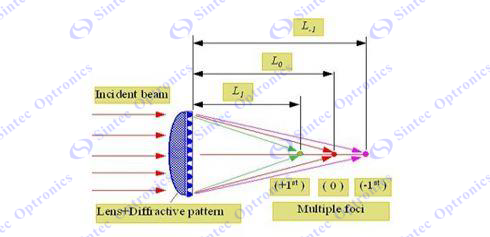

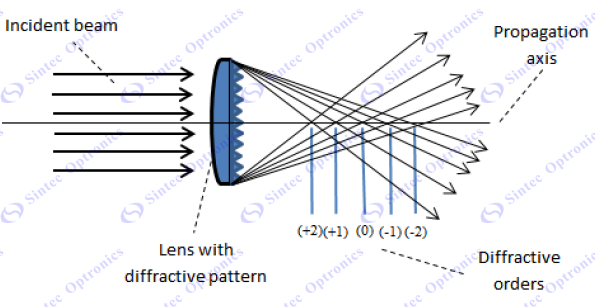

Multifocal

Lens

Multi-focal Diffractive Optical Element (DOE) allows to focus a single incident

beam simultaneously at several focal planes along the propagation axis.

We have a vast variety of solutions for multiple foci along the optical axis:

The Multifocal Diffractive Optical Elements (DOE’s) allow a single incident beam

to focus simultaneously at several focal lengths along the propagation axis.

From a collimated input beam (single mode or multi-mode), the output beams

focussed at a fixed number of focal lengths, predetermined during the design of

the Multifocal DOE based on the customer's system requirements.

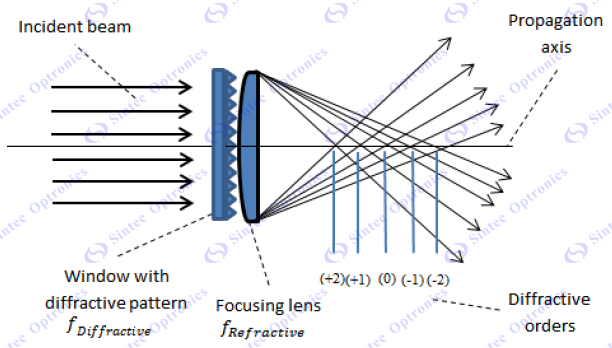

The Multifocal DOE comes in two configurations:

A DOE consisting of a Plano-convex lens with predetermined focal length, and a

diffractive pattern, etched on its Plano side.

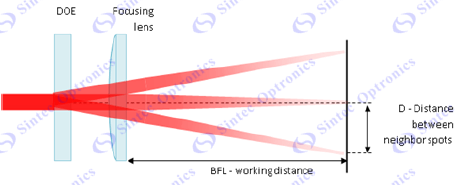

For more flexibility, a window DOE, thus, to get the foci spots at certain

distances, the user adds a regular focusing lens after the DOE. The lens focal

length determines the working distance (WD).

The Multifocal DOE can also be used as quasi elongated focus elements,

increasing effectively the depth of focus in applications such as laser glass

cutting and laser micro machining.

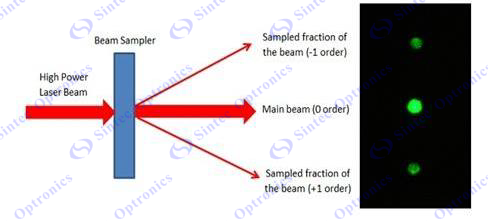

Beam Sampler

Diffractive beam samplers are used to monitor high power lasers where optical

losses and wavefront distortions of the transmitted beam need to be kept to a

minimum. In most applications, most of the incident light must to continue

forward, "unaffected," in the "zero order" while a small amount of the beam is

diffracted into a higher order, providing a "sample" of the beam. By directing

the sampled light in the higher order(s) onto a detector, it is possible to

monitor, in real time, not only the power levels of a laser beam, but also its

profile. A Laser Beam Sampler allows the high power beam (zero order) to

propagate undisturbed along the optical axis, but produces two side beams with

low energy. These two sample beams are located to the left and right of the main

beam (-1 and +1 orders), and are characterized by a given separation angle

between them and by a sample power ratio. It is relatively easy to modify the

sampling ratio upon a request of the customer.

Ring

Generator

A Ring generator transforms a laser beam into a ring (Diffractive axicon) or

into a multi-rings (Multi-Circles).

A laser concentric circles pattern transforms a laser beam into multiple

circles.

A concentric circles light pattern can be used for certain 3D mapping

applications, especially within pipe/tube objects.

A concentric circles pattern was recently proved to be the most appropriate

light pattern for certain 3D mapping applications, especially with pipe/tube

objects.

Each laser concentric circles is defined by its full angle and its number of

rings.

We offer, in addition to its standard products, the possibility to design and

manufacture a number of circles, separation angle between the circles and full

angle as requested by the customer, as a part of its custom design and

manufacturing capability.

We also design and manufacture diffractive axicon which is a DOE that splits an

input beam to a single ring.

An Axicon transforms a laser beam into a ring shape (a Bessel intensity

profile).

The ring's thickness will be equivalent to the diffraction-limited-spot size (of

the input laser beam).

An Axicon also images a point source into a line along the optical axis and

increases the Depth Of Focus (DOF). Each diffractive Axicon product is defined

by its ring propagation angle.

|

|

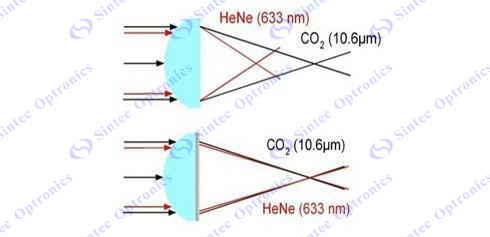

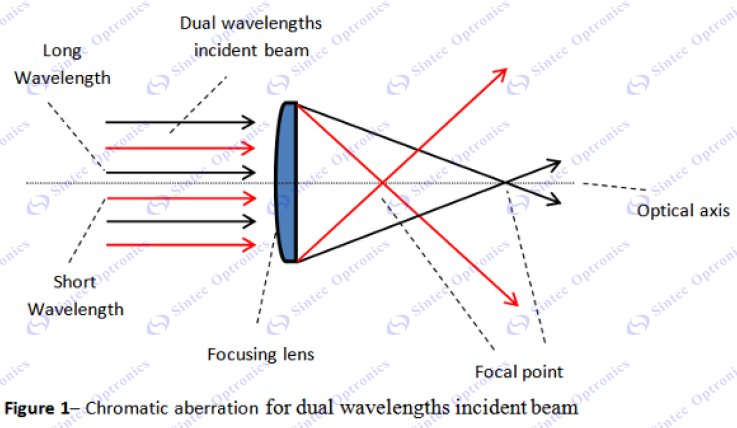

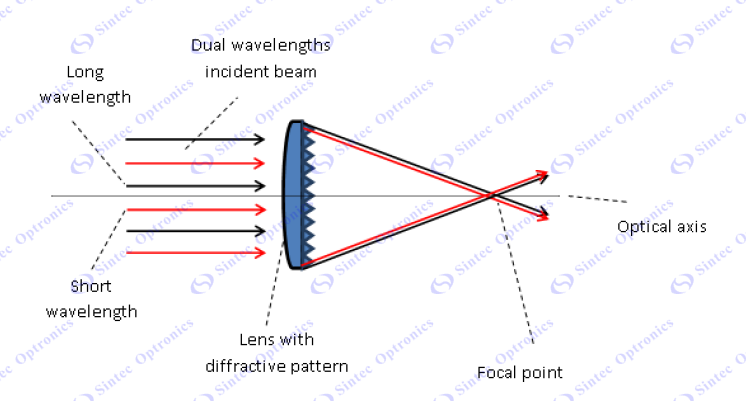

Dual

Wavelength

Dual wavelength beam combiners are diffractive optical elements used to combine

two incident beams with different wavelengths into the same focal point.

In multi-wavelength light beams the dual wavelengths are diffractive optical

elements used to combine two incident beams with different wavelengths into the

same focal point.

In particular, this focus combiner is used for combining CO2 laser focus and

visible aiming beam focus into a single focal point.

The Dual wavelength corrects the strong chromatic aberrations between a CO2

laser and its visible aiming beam.

This hybrid element, is based on a Plano convex lens with corresponding

diffractive pattern on its Plano side.

The focal length for both wavelengths is determined during the design, according

to the customer's application

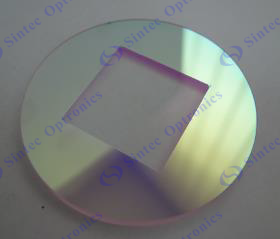

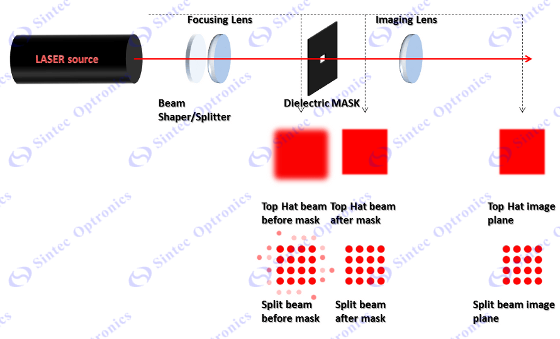

Dielectric

Mask

Dielectric

masks are glass substrates that have a very thin (~1um) reflective patterned

coating. The coated part reflects the incoming beam while the uncoated part

transmits the beam. The output in the near field will be very close to the shape

of the pattern. In the far field some diffraction patterns may appear. One

should not see significant diffraction, if one projects with a lens the output

of the mask to an image plane, as shown in the figure below. Dielectric

masks are glass substrates that have a very thin (~1um) reflective patterned

coating. The coated part reflects the incoming beam while the uncoated part

transmits the beam. The output in the near field will be very close to the shape

of the pattern. In the far field some diffraction patterns may appear. One

should not see significant diffraction, if one projects with a lens the output

of the mask to an image plane, as shown in the figure below.

Application:

One can narrow the transition region from a beam-shaper by using the Dielectric

mask as in the figure below.

One can also create any pattern that will be imaged with a lens. One cannot

manage the intensity profile within a spot.

Custom

Solutions

We offers customers the opportunity to obtain custom solutions such as:

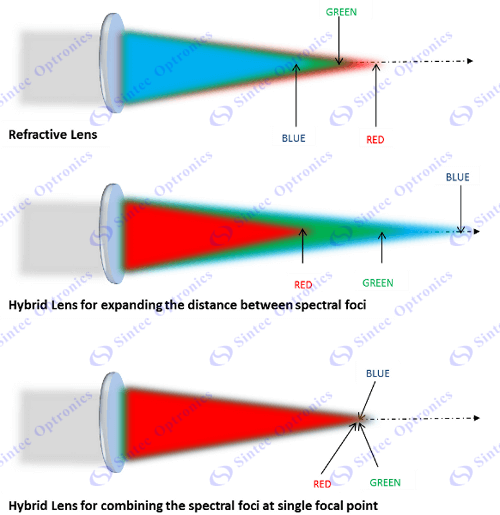

DOE for spectral dispersion of focal plane

In applications requiring multi-spectral focal

dispersion, we offer a flexible and compact diffractive solution. A refractive

lens alone has a small dispersive component, due to slight spectral dependence

of the lens material optical index. As a result, the spectral foci are discreet

but very close to one another. A diffractive surface is a compact effective

solution for "stretching out" or expanding the inter-focal distance between two

or more spectral foci.

On the other hand, a diffractive surface is also an effective solution for

combining foci of assorted wavelengths to a single focal point.

Lenslet array

Diffractive lenslet arrays are substrates covered

with a set of micro diffractive lenses. The arrays perform as diffusers or for

local focusing and sampling. A diffractive lenslet array has the advantage of

100% fill factor, much higher than refractive lenslet array. Aberration

corrected micro lenses for imaging systems are easily designed and fabricated.

We also offer 1-D micro lens arrays, lenslet arrays with shifted center.

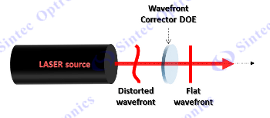

Wavefront corrector (i.e. for aberrations

correction)

When the wavefront is different from the desired

shape, a DOE element can be used to correct the deviation. The wavefront

deviation from desired shape must be constant in time, because each part of the

element introduces a specific phase correction.

Diffractive lens and Zone Plate Lens [ZPL]

Diffractive lenses are used to focus monochromatic

light (often laser light). A diffractive lens consists of a series of radial

rings or "zones" of decreasing width (known also as Fresnel zones). The

diffractive lens is a perfect lens which include spherical aberration

correction. As a general rule, diffractive elements work best at a single

wavelength. At any other wavelength the efficiency as well as image contrast are

reduced. However, the diffractive lens can be used also as chromatic aberration

corrector and, in this case, the image contrast will not be reduced. The

diffractive lens can be used also to reduce the number of elements in a system.

DOE Accessories

DOE Tuner for wavelengths range from 266nm to 1064nm

To answer the demand for fine-tuning abilities of various output parameters when

using a DOE, as: shape/spot size, separation/divergence angle, etc. our designed

a variable beam tuner, optimized for use with Top-Hat beam shaper, Homogenizer,

MultiSpot, and other DOE products. Another application is the fine-tuning of

incident beam size before DOE for Top-Hat application, where precision of

incident beam size is important.

The DOE tuner presents the following features:

Very low wavefront error

Beam expander x0.8-x1.2

No need to change module direction

Sliding lenses

Constant mechanical size

Fused Silica lens material

Input and output clear aperture = 23 [mm]

Module length = 120 [mm]

Max. Input Beam Diameter (1/e2): Ø8.4 mm (0.8X), Ø7.0 mm (1.2X)

Max. output beam size = 8.4 [mm]

*Max. incident angle = 0.5o

Wavelength range = 266-1064 [nm]

Other wavelengths upon request

*Defines angular limitation for Top Hat Beam Shaper or Beam Splitter usage.

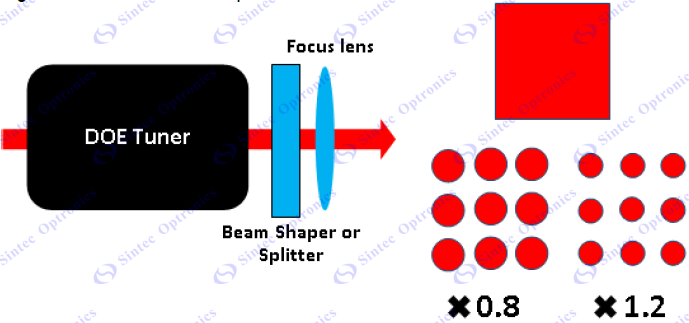

Different configurations for using the DOE-Tuner module:

Placing the DOE-Tuner before a DOE

Purpose – Fine tuning for input beam size

Benefit:

For Top-Hat beam shaper – achieves nominal beam size

For Beam-Splitters, Multi-Focal and Vortex phase plate – controls spot size

Key parameters:

| Parameter: |

Magnification < 1

|

Magnification > 1 |

| Spot size: |

Increases |

Reduces |

| Separation angle:

|

No change |

No change |

Figure 1: DOE-Tuner module placed before DOE

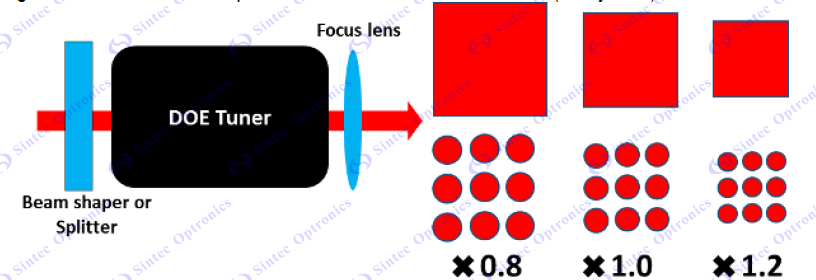

Placing the DOE-Tuner after a DOE

Purpose – controlling divergence of the output beam, allows to vary key

parameters of DOE in range of 80-120 %

Benefit:

Multi-Spot – controls the separation angle

Multifocal – controls the separation between foci

Top-Hat , Homogenizer & others – controls the image size

Key parameters:

| Parameter: |

Magnification < 1

|

Magnification > 1 |

| Spot size: |

Increases |

Reduces |

| Separation angle:

|

Increases |

Reduces |

Figure 2: DOE-Tuner module placed after DOE and

before focus lens (or objective)

Module for blocking unwanted spots \ energy

For applications as metrology and sensitive material processing, our designed a

compact universal module for blocking undesired spots of Multi-Spots or

parasitic energy of Homogenizers.

The module contains 6 lenses and a mask/aperture in the middle.

Each DOE design requires a certain mask/aperture according to customer’s specs.

Parameters and features of the module:

Max input beam diameter = 12 [mm]

Max full angle of DOE for 12 [mm] input beam dia = 5 [deg]

Input beam smaller than 12[mm] enables larger than 5 [deg] full angle for DOE

Module length = 90 [mm] (not includes DOE and focusing lens)

Outer diameter of module = 30.5 [mm] (lens diameter = 25.4 [mm])

Lenses material = N-SF11

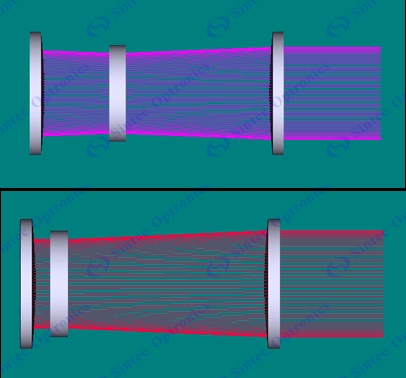

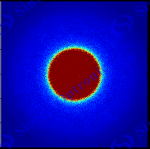

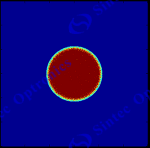

Simulation results of two DOEs with the module (right) and without (left):

| |

No module |

With module |

| Round Diffuser |

|

|

| Multi-Spot |

|

|

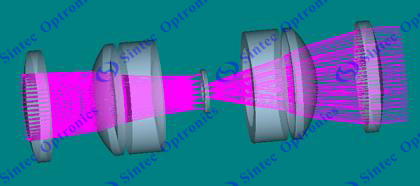

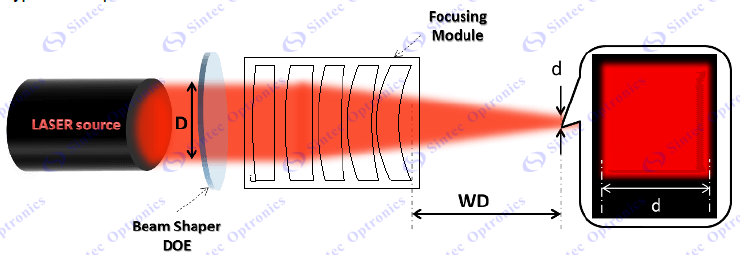

Focusing Module Optimized for Beam Shaper

For applications requiring an aberration-free image in focus plane, with a high

precision, we developed a new optimized focusing module to be used with our Beam

Shapers. A standard focusing lens (or objective) is normally optimized for

focusing a Gaussian beam and is not optimized to work with a Beam Shaper. Thus,

the use of standard focusing lens with Beam-Shapers often causes aberrations of

the Top-Hat image and requires special design of a focusing lens or module.

These aberrations will normally occur at small focal lengths, short wavelength

and large input beam. In order to solve this problem, we designed a focusing

module (with focal length 50 [mm]) adapted to our Beam Shaper working at 355

[nm]. The module contains 5 lenses, and the Top-Hat output is obtained at the

back focal length of the module. We offers customization of the module for other

wavelengths and focal length. The focusing module presents the following

features:

Free-aberrations module

Focal lengths: 30 and 50 [mm]

Wavelength (optimized): 355 [nm]

Material: Fused Silica

Max. input beam size = 12 [mm]

Optional - Objective correction collar

Typical set-up

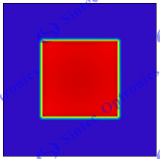

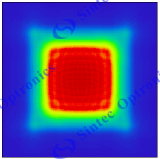

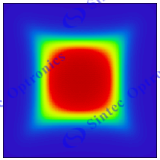

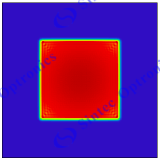

Comparison between Square Top-Hats result at image

plane obtained by different focusing elements:

| Ideal Lens

(Theoretical) |

Aspheric lens |

Standard

Focusing |

Our Focusing

Module |

|

|

|

|

| Simulation

results for a Square Top-Hat 100x100[μm2] in size, with (from left to

right): perfect lens (not real lens) for ideal spot, aspheric lens,

standard focusing module not optimized for use with a Beam Shaper and

our focusing module optimized for use with Beam Shapers. |

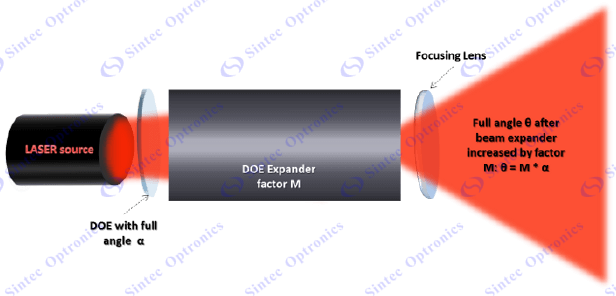

DOE Expander

We introduce a new module for modifying certain output parameters of a

Diffractive Optical Element (DOE).

The module reduces or expands the full angle of a DOE output by a magnification

factor.

Unlike standard beam expander, our module takes into considerations the

characteristics of our beam shaping, beam splitting and beam foci elements, thus

achieving superb results with minimal aberrations.

The module can be beneficial/suitable in the following cases:

Using the module together with a DOE, to create an overall function that would

be hard to manufacture by a single element

Adding our module to a standard, semi-standard or in-stock DOE with specific

full angle to change the full angle of the DOE thus avoiding any NRE payment,

and shortening delivery time

our is also able to customize the module according to the customer’s system and

request.

Specifications:

| Material: |

Fused Silica |

| Transmission: |

≥ 97% |

| Fixed Expansion factor: |

x5 and x9.4 |

| Product categories to be

used with the DOE expander: |

Beam Splitter, Homogenizer / Diffuser,

Top-Hat Beam Shaper, Vortex Spiral Phase Plate, Diffractive Axicon,

Multi-Circles |

| DOE expander optimized for: |

Square shape beam (as Top-Hat square or

Beam Splitter 2D square [9x9 spots for example]) |

| Suitable for: |

266nm to 1550nm |

Typical set-up:

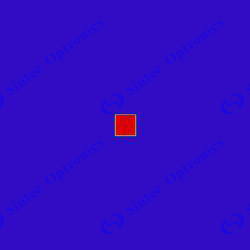

| Without DOE Expander |

With DOE Expander x5 |

With DOE Expander x9.4 |

|

|

|

| Far-field simulation results for a Square Top-Hat, from

left to right, without DOE expander 1.5x1.5[deg], with DOE expander x5

7.5x7.5[deg] and with DOE expander x10 ~14x14[deg]. |

Comparison between Square Top-Hats result at image

plane obtained by different expander module elements:

Flat metalens

Flat metalens |